Cobot FAQ

You Have Questions About Cobots? We Have Answers.

Read everything you need to know about implementing, maintaining, and scaling Cobots in your business.

Frequently Asked Questions

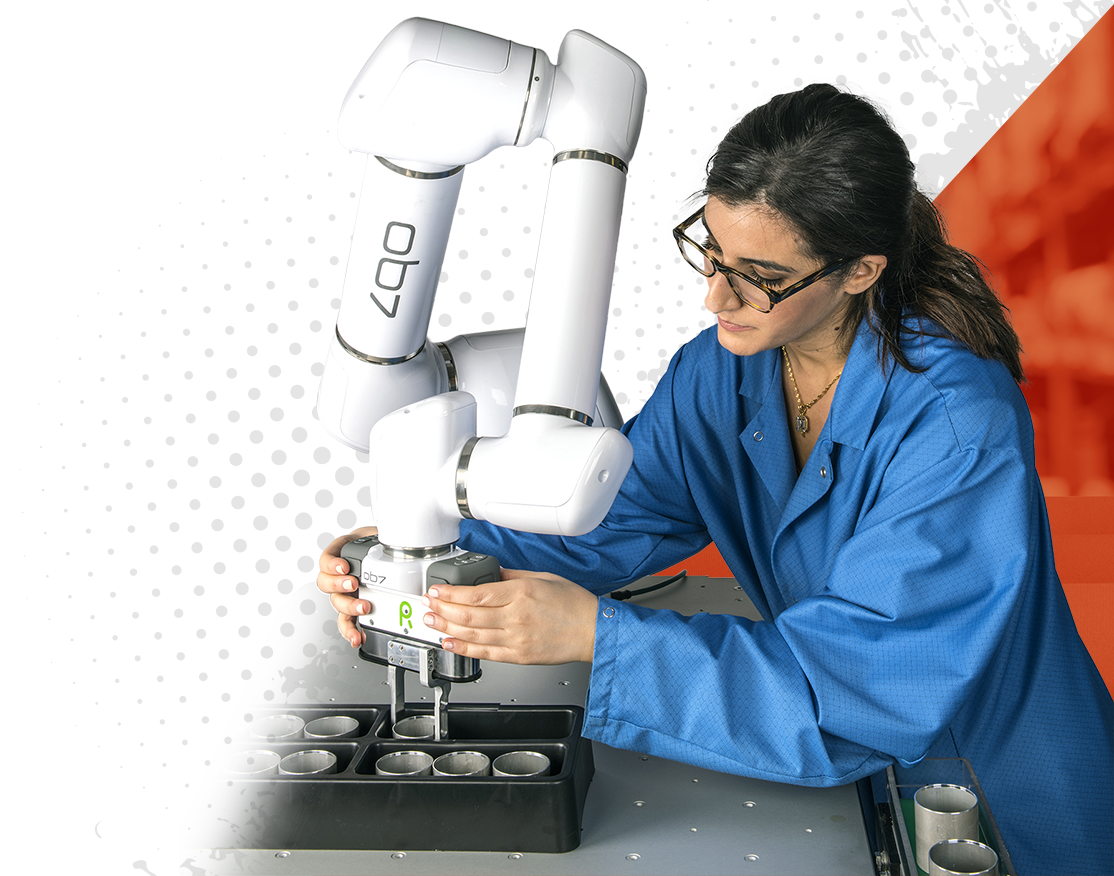

How Easy Is It To Teach The OB7 Family?

Easy, Just “show” the OB7 Family Cobot the task. It learns and repeats it.

Please contact us to provide a private demonstration and tour.

How Can I Move My OB7 Family Cobot From One Application To Another?

When an OB7 Family Cobot is on it’s stand, it can easily be moved from one job to another. Each time you teach your OB7 Family Cobot it learns and remembers the task for repetitive use. Ask us about our cloud backup package.

How Do I Purchase An OB7 Family Robot?

Please contact us to learn about purchasing, financing or rental options. We will be sure to get you everything you need to get your OB7 Family Cobot working for your business.

Are The Robot Hands or Grippers Interchangeable?

Yes. Please contact us regarding setting up the right gripper for each of your applications.

How Safe Is It To Work Alongside An OB7 Family Cobot?

The OB7 Family Cobot is safe because it has built in safety sensors. If the robot bumps into you it stops. This feature can also be used “on purpose” to inspect something. To put your OB7 Family Cobot back to work, simply give it a tap.

What Are The Benefits Of Having A 7-Axis Robot vs 6-Axis?

The “7” means that the robot has 7 joints. Most collaborative robots have only 6 joints or less. Having 7 joints or 7 axis points or 7 DOF (degrees of freedom) means that the robot can reach around something. For example, if your robot is operating a machine and it only has 6 joints, then you have to put the robot directly in front the work, which leaves limited room for a person to work alongside it.

How Much Weight Can It Lift?

We have Cobots that can lift up to 26lbs.

How Easy Is It To Program The OB7 Family Robot?

It is very easy. Actually, there is NO programming required. The robot “learns” to do jobs from you. Simply show the robot what to do and it remembers. Specifics like the number of parts to put in a box, or the number of stacks to make are entered on the robots wired keypad.

We Understand Cobots Are New For You, And We Are Here to Help You Set Up and Optimize Along the Way.

Cobot Experts Visit Your Business and Help You Visualize the Capabilities

On-Site Demonstrations Available

Fast Return On Investment

Financing and Rental Options Available

Free Trial Period Available

After You Implement a Cobot, Your Cobot Will Be Able to:

Run for Extended Hours With No Supervision

Repurpose Valuable Employees to More Dynamic and Fulfilling Work

Lower Your Cost of Production

A Reliable Source of Labor

Improve Operations

Hit Your Production Deadlines

When it Comes to Cobots, Seeing is Believing

Request An On-Site Demo

See Cobots At Work

Analyze Your Needs

Optimize Your Throughput